What are the factors that affect the performance of laser welding

Release time:

2024-10-30

Summary:

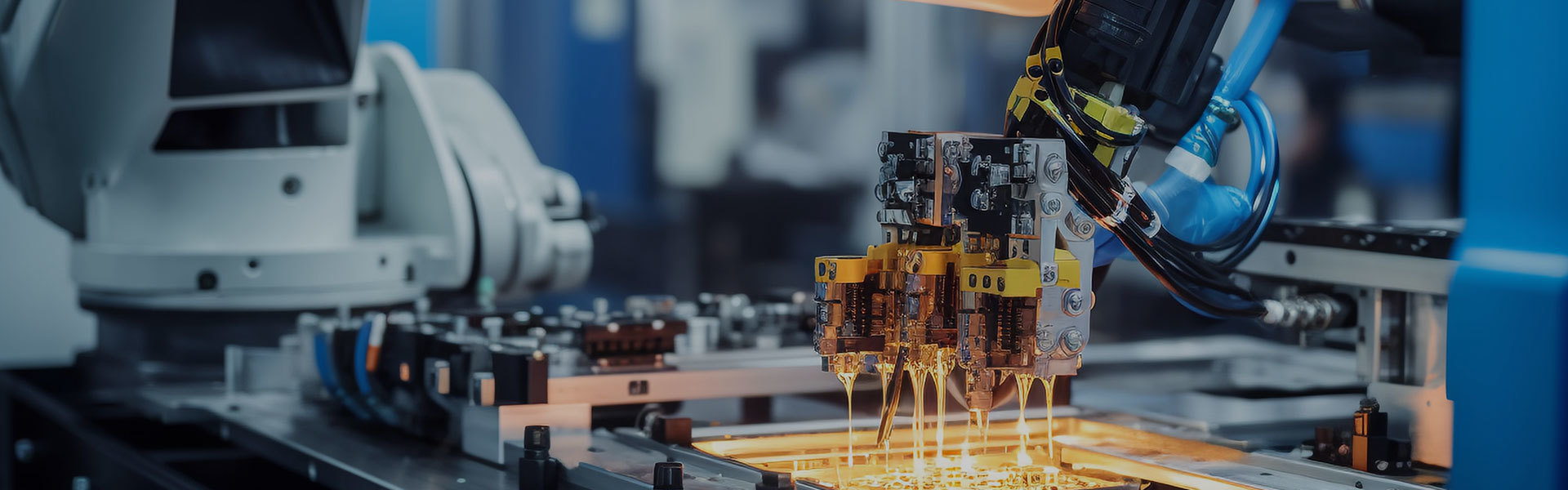

1. The welding process parameters that affect the quality of laser welding mainly include: laser power, welding speed, lens focal length, focusing position, shielding gas, etc.

2. Welding fixture: In the process of laser welding, the welding fixture is mainly used to accurately position and reliably clamp the welded workpiece, facilitate the assembly and welding of the welded workpiece, ensure the accuracy of the welding structure, and effectively prevent and reduce welding thermal deformation.

3. Welding equipment: composed of light and focusing systems, these systems have a certain impact on the quality of laser welding. The lasers used for welding mainly include pulse lasers and continuous lasers, and the most important performance is output power and beam quality. The quality requirements for lasers in welding are mainly the stability of beam mode and output power.

4. Workpiece status: The machining accuracy, assembly accuracy, and cleanliness of the workpiece welded by the laser welding machine are generally not filled with metal due to the small laser spot and narrow weld seam. If the assembly is not tight and the gap is too large, the beam will pass through the gap and cannot melt the base material or cause obvious undercutting and concavity. Of course, workpieces with higher welding quality requirements also have higher machining accuracy and assembly accuracy, especially for manual assembly before welding. It is necessary to ensure the height difference of the welding position, assembly gap, and cleanliness of the workpiece.

Previous Page

Previous Page

Real-time information

Copyright©2024 Shandong Haihai Laser Technology Co., Ltd.